Hard Chrome Grinding & Repair

Chromium coatings provide extreme hardness and resistance to wear and corrosion. This is a major factor in why it is so widely used in industries such as Aerospace, Nuclear, Heavy Machinery and applications for critical components.

Chromium coatings provide extreme hardness and resistance to wear and corrosion. This is a major factor in why it is so widely used in industries such as Aerospace, Nuclear, Heavy Machinery and applications for critical components.

But the benefit of increased coating thickness for hardness, longer wear life, and part use also creates another issue of uniformity and meeting project thickness requirements once applied. Which is why you need a certified and proven leader in Outer Diameter (OD) Grinding, Inner Diameter (ID) Grinding, Centerless Grinding, Vertical, Horizontal, Crush, Roll and Surface Grinding like Techmetals.

We ensure your industrial hard chrome parts meet precise thicknesses externally — as well as grinding the inside diameter of a part’s cylindrical opening to the exact size and surface finish to meet your needs. Techmetals can grind many materials besides hard chrome, including some exotic materials.

Trust in the company that has over 50 years experience in all facets of Chrome Grinding. From cylinders used in nuclear energy plants to machine parts and hydraulic equipment, Techmetals is the industry’s proven leader in hard chrome grinding services.

Note: All grinding dimensions are somewhat flexible depending upon the configuration of the part and the exact quality requirements.

Campbell CNC 3-Axis Vertical ID Grinder

- As large as 36” stroke, 45” internal diameter

- As small as 20” stroke, 4” internal diameter

Other Large Vertical ID Grinders

- 60” stroke, with 60” table; 72” swing

- Capable of grinding 10.5” – 55” ID

Cincinnati Horizontal Grinder

- 20 swing x 100” length; Up to 2,500 pounds

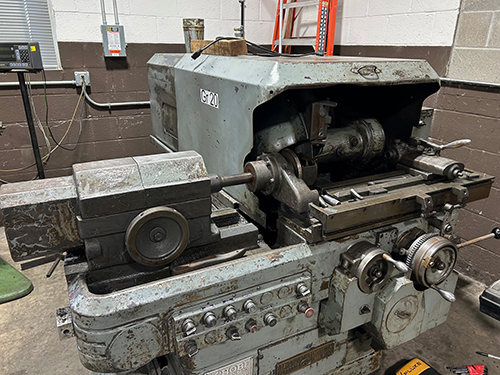

Norton Horizontal Grinder

- 10” swing x 60” length

- Up to 1,500 pounds

- Dimensional tolerances of +/- .00025

- Polishing available (no superfinishing)

Centerless Grinding (Thru-Feed)

- 1.5” – 3” OD x TBD

Thread Grinder

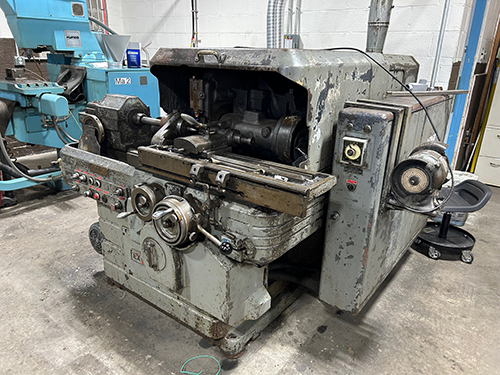

Crush Grinder

Crush Grinder