Tech Talk – Electroless Nickel

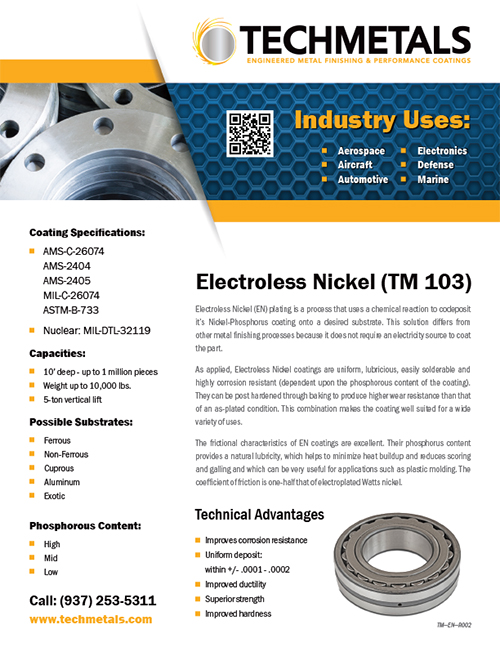

Electroless Nickel (EN) plating is a popular coating option for those requiring uniform thickness and a resistance to pitting, galling and corrosion. As the name would suggest, this process differs from other metal plating solutions because it does not require an external electric current to achieve results.

Electroless Nickel (EN) plating is a popular coating option for those requiring uniform thickness and a resistance to pitting, galling and corrosion. As the name would suggest, this process differs from other metal plating solutions because it does not require an external electric current to achieve results.

EN is a barrier coating that completely surrounds the substrate. It is both corrosion resistant and offers remarkable frictional characteristics, with a natural lubricity to minimize heat buildup. Grooves, holes, threads and even the inside of tubes are easily coated with a consistent thickness, and electroless nickel coatings can easily be soldered — making it an effective choice for the aerospace, defense, electronics and food production industries.

“Coating everything the chemicals touch” is a simplified way to describe this technique, but in reality it is much more complicated than that. There are many pre- and post-plating considerations necessary to achieve the uniform tolerances and hardness EN is known for. That’s why partnering with an industry leader such as Techmetals, with over 50 years of experience, can help save both time and expense — ensuring your electroless nickel projects are finished correctly the first time!

More than just “dipping and dunking” parts into a tank, the composition and chemistry of a nickel-phosphorous bath play a major role in how successful this hard coating will be in protecting suitable substrates.

Reducing EN Defects

A majority of defects in electroless nickel can be greatly reduced with the proper planning for all stages of plating. The most common issue is pitting and porosity — typically caused by either bath contaminants, substrate defects or improper cleaning of the substrate. The pre-plating process is critical to providing a uniform barrier, free of holes exposing the metal underneath.

The most serious defect from inadequate pre-plating is lack of adhesion. Poor adhesion to between the coating and substrate can result in blistering, flaking or defoliation and ultimately result in the exposure of the coated metal. The plating chemistry of proven EN providers such as Techmetals goes a long way in the success and confidence customers have in getting results they can rely upon. We administer regular cleaning, maintenance and checking of chemistry to prevent unwanted defects from damaging your plating projects.

Post-plating baking (heat treatments) help reduce the brittleness that can also effect the long-term benefits of EN. Cracking and flaking can occur from brittle coatings — exposing the substrate underneath and accelerating it’s corrosion and wear. This type of defect will definitely reduce the life of the part, reducing your ROI in the areas where it is used. Proper heat treatments will help harden the nickel coating, and add to the life of the coated part.

Trust in an Experienced Provider

With a half-century of experience in the electroless nickel plating industry, Techmetals is a resource you can rely upon time and time again. Our professionals will help guide you through the process and select EN options that fit your specific needs. We guarantee your parts are finished right — the first time! We have seen far too many people jump at unrealistic pricing, only to have to spend twice as much to rework parts. For environments where corrosion resistance, lubricity and uniformity of thickness are essential, trust in the experience and proven results of Techmetals.

See Techmetals’ Electroless Nickel capabilities…

To find out more about the benefits of High, Mid and Low Phosphorous EN plating,

please contact a Techmetals representative today by clicking here, or call us at (937) 253-5311.