Tech Talk – Anodized Aluminum & Titanium

Anodizing is a popular process in converting metals to improve their durability, resistance to corrosion and scratching. Available in a variety of colors, anodized finishes add to a part’s overall aesthetic appearance as well. Although anodizing can be implemented on a variety of metals, Techmetals focuses mostly upon Aluminum and Titanium substrates. Due to the fade-resistant colors and durability, many industries make use of anodizing including medical, aerospace, architecture and defense companies.

Aluminum Anodizing Process

Aluminum Anodizing Process

Unlike other coatings that are applied to a metal’s surface with processes like a paint or plating, anodizing actually interacts with the substrate, BECOMING part of the metal itself.

This is accomplished with the aluminum substrate being cleaned and placed into an electrolytic solution. The aluminum becomes the “anode” when an electrical current is added — causing the negative ions to attach to the now positive anode of aluminum. An additional barrier layer on top of the new substrate helps prevent further oxidation at the surface after anodizing. This process creates a hard, scratch-free metal that is perfect for use in extreme environments.

“Pore” Some More

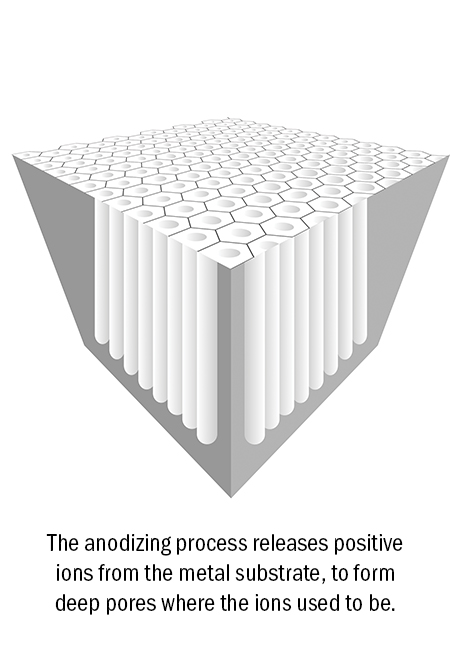

As the process of releasing of positive ions continues, this electrochemical process causes the aluminum to form deep “pores” where these ions used to be. These pores will continue to deepen into the substrate the longer the parts remains in the tank. The end result is a pattern of open columns/holes in the surface. If the process reaches a depth 10 microns, a natural aluminum oxide coating is produced that is hard and scratch-resistant. It can be sealed simply by rinsing it with water.

The aluminum oxide is rated 9 out of 10 on the Mohs scale, which is second only to diamond. The remaining surface combines with the negative ions to form aluminum oxide, which is also known as the barrier layer — which helps prevent against further oxidation of the surface metal.

Hard Coat Anodizing (Type III)

If greater corrosion protection is needed for extreme environments or with moving, mechanical parts, the electrolytic process can be continued to depths greater than 10 microns, all the way to 25 microns (or more). This hard coat anodizing is also referred to as Type III, and provides superior results. But attaining this level of hardness typically also adds time and expense to the process.

Colors That Never Fade

Colors That Never Fade

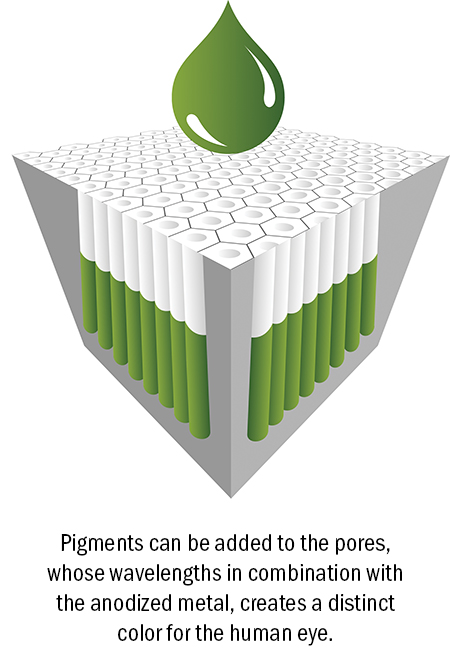

The amazing benefit to anodizing is that the long, hollow pores introduced into the substrate can be filled with tinted pigments to offer a wide variety of colors. The pigments fill up the pores to the surface, where they are permanently sealed off with the barrier layer. This creates color that cannot be scratched off, because they extend well below the surface of the metal. The only way to remove them would be to grind down the substrate itself to the depth of the pores.

The colors actually are achieved as a result of the added pigments interacting with the anodized metal. The different wavelengths of light reflecting from the anodized metal, viewed by the human eye, creates a distinctive color and shine.

What Materials Can Be Anodized?

Techmetals typically anodizes Aluminum and Titanium substrates (Type II and Type III), but the industry also is able to run the process on magnesium and even conductive plastics. The popularity of anodizing is driven by the fact that it is inexpensive, reliable and amazingly resistant to weathering — which is why it is so often used in architectural fittings.

See Techmetals’ Aluminum Anodize capabilities | View our Titanium Anodize Capabilities

To find out more about how Titanium and Aluminum anodize can benefit your business, please contact a Techmetals representative today by clicking here, or calling us at (937) 253-5311.