Choosing the Right Plated Coating for Improved Mold Performance

Steve Deisher |

Many mold makers have had great success with one particular coating and have used it for all of their applications. Unfortunately, there is not a magical coating out there that works in every situation. Many times, excellent coatings are used in the wrong applications.

Many mold makers have had great success with one particular coating and have used it for all of their applications. Unfortunately, there is not a magical coating out there that works in every situation. Many times, excellent coatings are used in the wrong applications.

Speaking from a plater’s viewpoint, one of the major challenges is correcting problems caused by another plating company applying the wrong coating for a particular application. When plating is used properly, the positive results can be stunning.

There are many causes of wear and corrosion in plastic molds that can contribute to greatly reducing mold life. Plating can solve many of these situations. However, these coatings also can improve the performance of molds in many other ways. A basic knowledge of plating is necessary to make an educated choice for properly solving your particular problems. There are more than eight different plated coatings for molds. It is the intent of this article to help mold makers take advantage of these benefits.

Types of Plating

There are two basic types of plating – electrolytic and electroless. Electrolytic plating requires electricity to make the process occur. There is a positive and negative charge. The positive is called the anode and the negative is the cathode. The part to be plated gets the negative charge so it becomes the cathode. The anode is made of conductive metal – such as lead – and becomes the source of the positive charge. Hard chrome plating is one of the oldest electrolytic plating processes. The chromic acid solution is the medium by which the current transfers. When the plating process occurs, the negative and positive ions transfer in the solution causing a metal (chrome) to reduce onto the base metal of the part being plated. A good analogy would be to look at it as the reverse of EDM. Because the process uses electricity, the plater is constantly fighting against the laws of nature.

The old rule still holds true: electricity travels in straight lines and goes to the closest point. On sharp corners there will be a heavy buildup of plating. In the recesses, the plating will tend to be thinner.

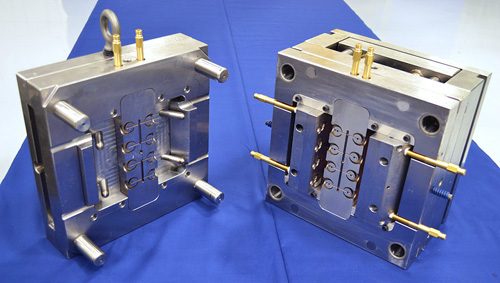

Electroless plating, such as electroless nickel, is just the opposite of electrolytic plating. Additives in the solution take the place of electricity. These additives are known as reducing agents. Since all metals have a charge, when the reducing agents detect the base metal charge in the plating bath, they start to react. This causes the metal in the bath solution – in this case nickel – to reduce onto the base material of the part being plated. No electrical current is required. Wherever the plating solution touches the base material, the plating will adhere. This gives the plated part a very uniform deposit and the plating thickness can be controlled within .00005-.0001, even on complex shapes.

Within these two families you have several types of deposits. These different types include composite and alloy deposits. As a generality, if you need a perfectly uniform deposit in a complex shape, electroless nickel deposits are best. However, hard chromium is the hardest deposit and has excellent release.

How to Choose

When choosing plating for your mold or mold components, you must first identify the problem to be solved or the problem to be prevented. The first question you should ask is “What is the cause of this problem? Is this problem the result of corrosion or wear?” If the component has previously been plated, this may be difficult to determine. Have your plating vendor look at the component to determine if it has been plated and if so, what type of plating was used.

Abrasive wear can occur on compression molds that use mineral or glass-filled materials. These materials can cause a scouring action on the mold surface. In transfer and injection molding of thermosetting materials, wear often is detected in the high flow areas such as in the runners, gates and portions of the cavities and cores that are directly opposite the gates. In injection molds for thermoplastics, wear most commonly appears on the surface opposite the gate.

Most damage results from continuing to run the mold after flashing occurs. However, there are other sources of damage of which to be wary. These sources can include water contacting unprotected surfaces, causing corrosion; water condensing in the molds; seepage through porous metals; and leaky pipe fittings and “O” rings. Where chillers are used for mold temperature control, condensation of moisture on the mold surfaces can sometimes occur even while they are in full operation. Careless handling of hoses and feed lines during hookup can leave water on the mold surface. Corrosion is progressive and even if the molds are stored after being sprayed with an antioxidant, a few drops of water or condensation can cause tremendous and costly damage.

Another source of damage is attacks from acids. These acids may form after exposure to corrosive materials generated by thermoplastics decomposition (often due to overheating). Overheating can occur in the plasticizing cylinder, the hot runner system or in the mold cavities as the result of too small gates, or inadequate venting or cooling systems. During the molding of PVC, a small amount of hydrochloric acid is formed, which is extremely corrosive to the mold cavity.

Electroless nickel, by its very nature, is an excellent corrosion barrier for most mineral acids, whereas these acids will attack chrome. Stainless steels also can be susceptible to attack by chlorine or fluorine containing plastic, leading to pitting or stress corrosion cracking. This can be eliminated with a high phosphorous electroless nickel deposit over the stainless steel.

With so many different types of molding and even more types of materials available, there is no easy answer as to which coating will best enhance performance. An investigation into these coatings is worthwhile because if your molding operation is left unprotected, it can create corrosion, erosion, materials flow or release problem. The proper plating can make all the difference. Before you make that critical decision, call your plating vendor of choice and ask which coating will work best for your application.