TM111 Hard Chrome

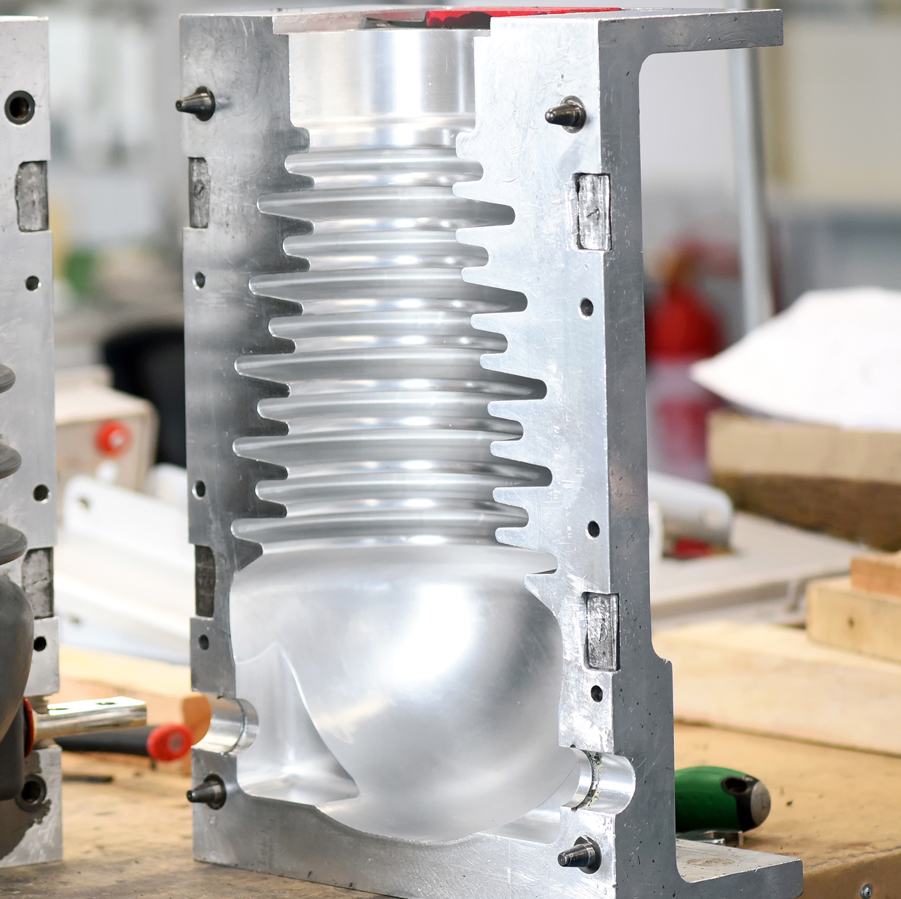

TM 111 Electroless Nickel (EN) with a Hard Chrome deposit overlay, offers the best qualities of each in a single coating solution. The top, hard chrome layer has a hardness of 67 Rockwell C and a very low coefficient of friction. This provides excellent wear properties for the finished part.

The Electroless Nickel base produces a uniform, corrosion-resistant barrier coating – totally encapsulating the unit in a corrosion-resistant, porous-free coating. The end result is superior corrosion resistance and uniformity. The EN base will plate whatever surface it is able to wet when in solution – all edges, corners and most blind holes.

Technical Advantages:

- Superior corrosion resistance

- Low coefficient of friction

- Non-adhesive

- Porous-free coating

- Non-magnetic properties

- Excellent anti-seizure characteristics

- Uniformity and accuracy are easily maintained by varying the amounts of each coating

- Improved wear properties

- MPR 1059 Nickel Chrome: (NAVAIR/NAVSEA/NAWCAD)

Click here for complete information, specs and downloads…

Request a Quote…