Slaying the Hard Chrome Dragon with TM-Xcalibur

Tim Pennington |

In the endless pursuit for a replacement for hard chrome, Techmetals Inc. (Dayton, OH) may have a shining example of how to provide comparable corrosion performance, while also being environmentally friendly.

In the endless pursuit for a replacement for hard chrome, Techmetals Inc. (Dayton, OH) may have a shining example of how to provide comparable corrosion performance, while also being environmentally friendly.

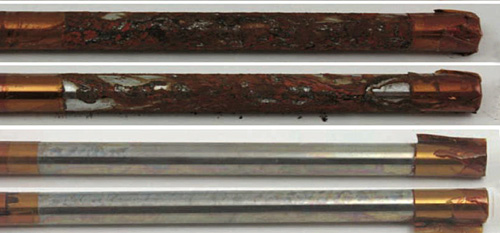

TM-Xcalibur is a hard chrome replacement coating that Techmetals says can have low coefficient of friction, can out perform chrome in wear applications, and provide as much as three times better corrosion resistance of chrome.

“This coating has some leveling properties, which helps maintain surface Ra,” says Phillip Brockman, Techmetals’ director of business development. “It is mainly used in high wear, anti-galling, release, or corrosive type applications.”

TM-Xcalibur can be applied to all ferrous metal and most nonferrous metals. Brockman says the coated hardness is 520 to 750 Vickers, but after heat-treatment of 400° F for six hours the hardness increases to 900 to 1100 Vickers.

The company says that data testing has shown that in the pin-on-disc wear testing, TM-Xcalibur has outperformed hard chrome results by two to four times in wear resistance.

Techmetals customer Federal Mogul Corporation (Southfield, MI) has tested TM-Xcalibur in its attempt to have a suitable hard chrome replacement ready in case they need it.

“We tried it in the molding side of our business, and it worked as well as chrome,” says Jay McClure, a manufacturing engineer for Federal Mogul. “Right now if we get out of chrome, this will be our first alternative.”

Federal-Mogul is a leading global supplier of powertrain, chassis and safety technologies for original equipment manufacturers of automotive, light commercial, heavy-duty, agricultural, marine, rail, off-road and industrial vehicles. Their aftermarket include AE engine products, ANCO wipers, Champion spark plugs and wipers, Fel-Pro gaskets, Ferodo brake pads, Glyco bearings, Goetze piston rings, MOOG chassis products, National wheel-end components, Nural pistons, Payen gaskets, Sealed Power engine products and Wagner brake and lighting products

McClure says Federal Mogul has been searching for a hard chrome alternative for decades, since environmental problems associated with the plating process came to the attention of the EPA.

“We’ve been looking for a replacement for 20 years, and we’ve tried everything you could think of but nothing works as well as hard chrome,” he says. “I haven’t tried XCalibur for 15 years to see if it will last as long as chrome, but in my initial study it looked as good as chrome for the amount of time I tried it.”

McClure said he put XCalibur in a mold press side-by-side with hard chrome and let it run.

“It performed just like I expected, just a like a newly chromed part to run,” he says. “It stayed shiny, and no flash stuck to it. It really ran fine. It did well in the mold cavities without any issues.”

Brockman says that TM-Xcalibur was benchmarked against hard chrome and as deposited electroless nickel. Against hard chrome, Xcalibur had a penetration depth of 0.2 m, a wear rate of 1.0 x 10^-3 mm, 3/hr, and a relative wear rate of 1. Hard chrome’s numbers were a penetration depth of 1.5 m, a wear rate of 2.3 x 10^-2 mm, 3/hr, and a relative wear rate of 23. Electroless nickel came back with a penetration depth of 10.5 m, a wear rate of 2.9 x 10^-1mm3/hr, and a relative wear rate of 290.

“TM-Xcalibur surpassed chrome corrosion resistance by three to 10 times in standard salt spray testing results,” Brockman says. “The coating is bright, scratch resistant, and is environmentally friendly.”

Techmetals says TM-Xcalibur’s applications include aerospace, DoD, automotive, tool and die, electronics, hydraulics, rotating equipment, and oil and gas among others.

Besides being a researcher and consultant for plating companies, Techmetals is also an engineering metal finisher. Its 125,000 sf2 plant has capacities that include hard chrome, tin, composite diamond coatings, silver, nickel, cobalt, electroless nickel, anodize and other coatings on small parts and parts weighing up to 10,000 pounds or more.

In fact, their capabilities is how Federal Mogul first came into contact with Techmetals several years ago.

“We contacted Techmetals a few years ago because we wanted to get out of hard chrome,” McClure says. “We actually were going to have Techmetals do our hard chroming for us just so we could get out of it. But we put that on the back burner, and are sticking with hard chrome until we have to make a switch.”

Brockman says Techmetals’ corporate vision is “to be so good, our customers brag about us.” They may be getting their wish.

“They tell me this is the closest they’ve come to hard chrome, and I would have to agree with them,” McClure says.

To learn more about Techmetals, please visit their website at www.Techmetals.com, or contact them at 1-937-253-5311.